What is LNG?

Liquefied natural gas (LNG) is natural gas that has been converted into a liquid state through a process of cooling and condensation. It is odourless, coluorless, non-toxic, and non-corrosive.

LNG plays a vital role in the global energy landscape as a clean and versatile fuel source, with applications ranging from power generation to heating, industrial processes, and transportation.

In the liquid state, LNG is 600 times smaller in volume than in the gaseous state, which greatly facilitates its transport and storage. LNG can be considered the cleanest fossil fuel, as it generates less CO2 than other fossil fuels.

Cryogenic insulation with CRYOLENE

Storage tanks and vessels in various industries come in a wide range of sizes, shapes, and media temperatures to suit different processes. However, they share a common need for reliable insulation that fulfills all the process requirements. This includes maintaining stability, preserving temperatures (both heat and cold), and ensuring safety measures, such as protecting personnel from hot or cold surfaces. Effective insulation plays a crucial role in meeting these needs.

The construction of storage tanks for cryogenic fluids such as LNG, liquid oxygen, or nitrogen used in chemical, or combustion processes has very demanding requirements. It is not only challenging to build these tanks, but the insulation systems used must also meet strict standards.

Adapting to Changing Tank Volumes

One of the main challenges is that the tank volume changes as the liquid level goes up or down. Therefore, the insulation material needs to have both good compressibility and resilience in order to adapt well to these fluctuations. To meet this requirement, ISOVER has developed the unique CRYOLENE solution for the insulation of cryogenic tank walls and roofs.

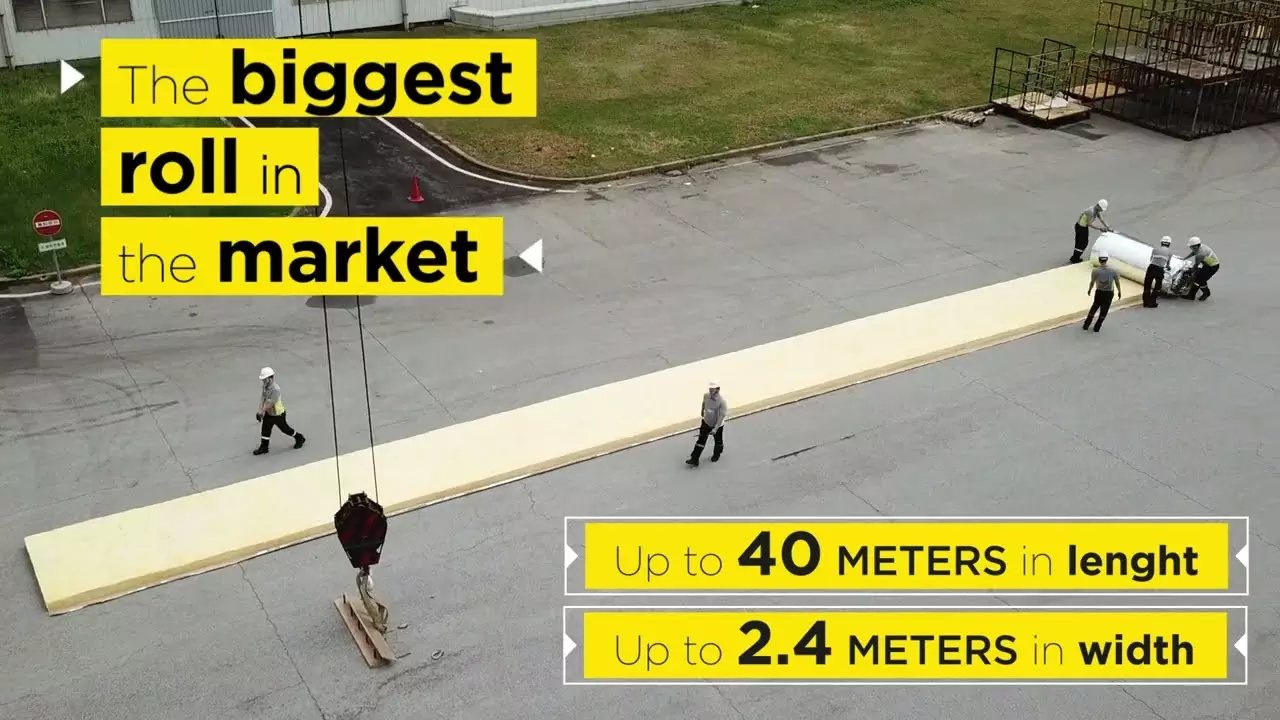

CRYOLENE products are highly resilient mineral wool rolls designed to retain their fiber elasticity over time at temperatures ranging from -170°C to +120°C.

Efficient Installation and Thermal Performance

Different solutions have been developed for tank shells and suspended deck insulation.

The product’s extended length means that CRYOLENE solutions are easy and fast to install, with reduced thermal bridging. Different facings, such as reinforced glass tissue or reinforced aluminium foil, give CRYOLENE products high tensile strength.

Proven Reliability

The properties and performance of CRYOLENE have been extensively tested by external laboratories, and the products are well-proven through decades of successful use worldwide in chemical and LNG applications.

Discover CYROLENE, our range of insulation solutions for cryogenic tank walls, suspended decks and pipe connections.

CRYOLENE, a full range to insulate LNG storage tanks

CRYOLENE insulation can handle high hot and cold temperatures, from -170°C to +120°C. It has a low binder content, which makes it remarkably safe in case of a fire. The reinforced aluminum foil covering is made to be extra strong, so it doesn't get damaged when the annular space is filled with perlite or settles down.

Depending on the type of covering, CRYOLENE has two classifications:

- A1 with glass tissue (V.V.)

- A2-s1, d0 with aluminum foil (A.A.).

The CRYOLENE range is available in different shapes, for wall, pipe, and deck sections.

CRYOLENE 682 is suitable for large wall sections and offers better thermal performance with fewer joints and bridges. It reduces installation time by 75%, improves safety on-site, and makes installation easier.

CRYOLENE – At the service of our customers

ISOVER has acquired extensive expertise in LNG insulation by taking part in significant projects around the world. Through this experience, the company has successfully improved solutions that harmonise performance, practicality, and reliability.

ISOVER places important attention to fulfilling its obligations to customers. ISOVER ensures the delivery of high-quality products by following strict quality checks and getting certifications both internally and externally. ISOVER also prioritises delivering its products on time by ensuring their availability when customers require them.

Our businesses are represented worldwide covering local products, services and other information.

Product range

TECH Loose Wool QN

Nuclear-quality-designed special loose white glass mineral wool roll

CRYOLENE 684 AA&VV

Resilient glass mineral wool blankets engineered for cryogenic applications

CRYOLENE 682 AA&VV

Resilient glass mineral wool blankets engineered for cryogenic tank walls

CRYOLENE 681 AA&VV

Resilient glass mineral wool blankets engineered for cryogenic tank decks